One local service manager of a GM dealer told me that he has seen multiple technician applicants who managed to fiddle around with a small block Chevy in their backyard until they finally got it to start, and believed that one wrench-and-steel conquest and a couple of brake pad swaps on friends’ cars qualified them for an A-tech slot in the dealer service bay. He doesn’t hire them.

By far, we all know the best skill gained comes from performing lots of real repairs on vehicles people will be driving, day after day, one after another. And no matter how many vehicles we troubleshoot and repair, we’re going to encounter some that we will remember for many a year. For me, well, I can think of dozens. But in those moments when we think we know what to expect when we draw a work order but get blindsided, it’s downright annoying.

And then it gets personal – you against the machine – usually one-on-one, slugging it out, sometimes over several days. That kind of meat grinder works well for any skill level from my automotive students to full-blown techs. We never stop learning, and the tough ones put iron in our souls. And for those who are just getting started in this business or are reading these words as a consumer, this, ladies and gentlemen, is what we do.

The Durango

This one came in with a simple “Check Engine” light. And the initial annoyance was that this Durango started out by refusing to talk to us on the enhanced line, and while we did agree to have a look at the MIL issue, we aren’t doing network/comm stuff this semester, so I had my guys back out of the enhanced screen on and dive into the generic OBDII side – which is always a good idea anyway, because what doesn’t show up in the enhanced room might appear in the generic one.

And on the generic comm line we found a P0520 code – that familiar Chrysler oil pressure sensor circuit failure. That’s the one the PCM monitors even if the cluster doesn’t have a gauge. We’ve done these on the V8 Chargers – a few of them, anyway – and so I told the owner of the vehicle we could handle it – no problem. And we did. But we were surprisingly annoyed at just how involved that job turned out to be. And there were pitfalls.

This one was a 3.6L, and the upper and lower intakes had to be removed to access the rear of the oil cooler, where two different sensors are nestled. We packed the intake ports full of rags on the heads at this point for obvious reasons while the sensor swap was under way.

The oil temperature sensor was directly above the oil pressure sensor and also directly in the way, so it had to be disconnected and removed, and then the oil pressure sensor connector had to be disconnected, which turned out to be aggravating because the connector trigger was facing down and inaccessible. So, we’d need to turn the sensor to access the connector trigger. Piece of cake, right? Well, a thick, heat-stiffened wire harness was passing right next to the sensor and that harness was unyielding. Remember, we couldn’t disconnect the sensor wire connector, so a socket was a no-go. And a one and a sixteenth wrench is nice and beefy for turning big, tight fasteners but it doesn’t fit in a tight spot worth a toot. This sensor wasn’t all that tight (1/8 pipe thread), but it was tight enough that even if you managed to shove the open end onto the sensor flats, we couldn’t turn the sensor even a little without that heat-tempered 1.5-inch-thick wire harness forcing the fat wrench off the sensor flats. This was an annoying surprise.

I did some bench grinder work on one side of an old chopped-up 1-1/16 wrench I had already modified for something else, and we used that modified wrench to work the sensor around, getting it indexed so we could finger the trigger and remove the connector. We continued to use that same wrench to worry the sensor out, because even with the connector disconnected the harness prevented the use of the sensor socket. We finger-started the new sensor and worried it back in until it was good and tight, then we reinstalled the previously removed oil temp sensor and reconnected all the wires. Then we went back together with it using new intake gaskets and whatnot.

The job was a victory, but it took a couple of dedicated students just about an entire day to make it happen. That surprisingly annoying task was behind us, and so was the Durango and its MIL light.

The 2005 S10

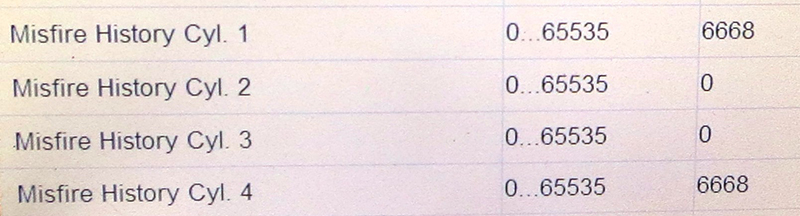

This 4-cylinder S10 was a beat-up little farm truck that came to us with the owner complaining of a hesitation, and sure enough it stumbled on takeoff. But even after acceleration this dog was anemic at best. We applied the fuel pressure gauge to determine that the pressure was always steady and strong. We got a P0300 code, and on the scan tool misfire screen, cylinders 1 and 4 had recorded LOTS of misfires – thousands of them. Initially, I’d have believed there was a coil pack issue, since coil packs fire companions and 1 and 4 share the same coil on those. But this one is fitted with COP coils. What else could cause multiple misfires on companion cylinders? Was the valve timing skewed?

Just for grins I had the students check compression, and they found that the firing cylinders actually had less compression (175 psi) than the ones that were reporting misfires (210). The two rear spark plug wells were awash with oil, so we did the valve cover while we were there. Those higher compression readings might have been due to surface quenching from unburned fuel, but it was strange, and we couldn’t see a lot of difference in the spark plugs on the misfiring cylinders and the plugs on the ones that weren’t reporting misfires. Just to be sure there wasn’t a cam/crank issue, we PICO scoped the cam and crank traces to check for a timing situation, but everything lined up perfectly so we moved on.

After the valve cover gasket was in place, we tossed a couple of coils in the reportedly misfiring holes along with a full set of plugs, but nothing changed – misfires were still being recorded on 1 and 4, but it honestly didn’t feel like it was misfiring – it only seemed sluggish and a holding a rag in hand by the exhaust didn’t show any puffing. And the ACE Misfire Detective was confusing enough as to be no help at all on this one.

At this point, I decided to focus on the MAF sensor, because, according to my professional eye, the airflow readings didn’t seem to reflect reality, even when MAF was the only PID being traced. Interestingly, when we unplugged the MAF and did a test drive, the truck ran like brand new, and as I peered through the sensor with my streamlight the hot and cold wires seemed dirty – but cleaning the sensor only helped a little. This one needed a new MAF, but when we showed the farmer how good it ran with the sensor disconnected, he opted to drive it that way and ignore the MIL, since most of the time he’s using this truck to herd cows. His call, I guess. But the surprisingly annoying part of this job was that the misfire counter pointed us in the wrong direction initially.

The Edge

One of my colleagues drives a Ford Edge – awhile back we had to replace the brake booster (which was dreadfully annoying). Speaking of brake boosters, for a short side story (annoying) we had to replace the booster on a 1998 F150, and after we changed the booster, the brake lights were always on because the booster pushrod had some flashing on it that had to be ground off so it wouldn’t keep the switch closed all the time – didn’t see that coming!

On the Edge this time around she was having issues with her A/C. She reported that it’d run for about 30 minutes and then get hot on one side (dual zone), so, after we duplicated that and saw erroneous readings coming from the blend door actuator on the driver side, we replaced that actuator with a Dorman unit and let her try that, but after a few days, the Edge returned with the complaint that the A/C that would totally stop cooling after about 30 miles of driving.

In addition to that issue, her radio would always begin to search wildly for no reason after a few minutes – obviously an APIM problem (the 2012s are problematic this way), which we figured might have something to do with the A/C issue, but it didn’t. We did that wacky Ford PTS software update/reflash with the IDS (with some guidance from Joey Henrich’s AE tools guy), but the APIM radio function still wasn’t fixed, so on her orders, we ordered a rebuilt replacement APIM from Ford. The core charge is $500 on one of those, by the way, and replacing that unit fixed the radio – but by the time the APIM came in, we had already figured out the A/C problem.

After letting the A/C run in the service bay with the recycler connected so we could watch the pressures, we noticed that when the register got warm, the low side had drifted into the negative and the high side was hung at just over 150 psi – much lower than it had been when the A/C was cooling. That was our smoking gun.

An expansion valve took care of that one. As an aside, the owner had, on a previous day dropped by a dealer shop when she was in another town for a quick check of the A/C and they told her she’d need a $1500 evaporator case replacement to take care of the no-cooling issue because, in their words, “the actuators aren’t communicating.” I’m not sure what pocket to put that in, but she was glad she had opted against letting them do that!

Mysterious bearings

Another one of my colleagues drives an old Sentra that had developed a nasty noise, and after we determined by doing some tire-swapping that it was a bearing noise, we went out of our way to make sure we got the right bearing – these can be really tricky sometimes (can I get a witness?), and this one was no exception. I told the owner that we might wind up having to replace both bearings and he gave us his blessing. Using the Chassis Ear® we thought we had it pinpointed as the one on the left front, (swerving seemed to point to that bearing too), but when we broke it down I could have a good look at those shiny balls and race, I could tell that we had misfired on that – Mr. Murphy is alive and well, you see. But we were at the point of no return, so we installed that bearing and drove it again – no change.

With that, we attacked the other bearing, which still didn’t show any brinelling or wear as we had supposed, but we did notice that the grease in that bearing was discolored – instead of a healthy cream color it was kind of brown, and even though the balls and races looked good, replacing that bearing eliminated the noise. We had no smoking gun, but we had a solid fix. That always bugs me, because I like visual verification of that kind of thing. Granted, you don’t always get that with transmission or ring and pinion gears, but with bearings you usually see something. This time, not so much.

The Altima – A perfect storm

This one came to us with the story that a guy at a shop in another town had replaced the transaxle, but that after only two hours of driving around, the transaxle had started slipping and then stopped pulling and now the guy who had changed the transaxle was telling them it needed a flywheel. So they brought the car to us with a used flywheel they wanted installed. How tough or annoying could this one be?

We worried that CVT out of there to find that, although we had unbolted the torque converter, it stayed attached to the engine when the CVT was removed. Furthermore, it didn’t want to come off – at all. But it was rattling around loose. After using a big prybar and a hammer and whatever else it took, I managed to get the torque converter on the floor. It was at that point that I discovered a very serious issue.

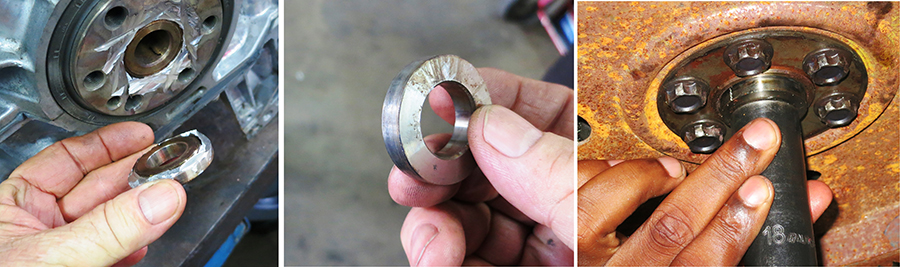

The flywheel had broken smoothly enough that the engine was spinning the now-separate center of it. The outside of the flywheel and the torque converter were both sitting still while the engine was spinning to beat the band, and the pilot bushing those Nissans have in the back of the crankshaft had been whirling on the pilot of that converter until the pilot had become red hot and had swelled to the point that the pilot bushing came out of the crankshaft when we pried the converter out of there. This was surprisingly annoying, and that wasn’t all.

This was ultra-nasty, because all the information I found was that the bushing in question is not obtainable apart from buying a replacement crankshaft. Granted, with the right dimensions, a machine shop could have made us one on a lathe, but machine shops are hard to find these days.

As it was, this customer got lucky. It just so happened that I had a defunct 2004 Altima powerplant sitting in the engine shop that had been swapped out because it was knocking, and I got the bushing out of that one. It was an annoying process, but with a high-speed cutter, we made it happen. The bushing was a perfect fit, and with a replacement torque converter and the CVT back in place, the Altima was good to go.

The customer asked if the previous tech had done anything wrong to cause this. My answer was that he hadn’t, and that was that. I told them about a transmission we had replaced in a four-wheel drive Expedition that came back a month later with a busted flywheel it’s always annoying but sometimes it happens.