In addition to selecting top-notch people with little or no body shop experience and training them to meet their desired performance and customer service levels, leveraging the technological, management and educational expertise provided by key suppliers is an important asset for driving profitability at Glaser’s Collision Center.

|

At a Glance: Glaser's Collision Center |

|

Jefferson, Ky. Headquarters location |

|

Gene and Susan Glaser Owners |

|

3 No. of shops |

|

30 Years in business |

|

48 No. of employees |

|

9 No. of DRPs |

|

Jeffersontown - 16,000 Shepherdsville - 10,000 Louisville - 7,500 Square footage of shops |

|

59 Total number of bays |

|

68 Average weekly volume |

|

3.1 days Average cycle time |

|

$2,291 Average repair order |

|

PPG Paint supplier |

|

Car-O-Liner Frame machine used |

|

CCC One Estimating system used |

|

www.GlasersCollision.com Website |

With three shops in the region around Louisville, Ky., “Our vendor relationships haven proven to be very beneficial for our continued success. We strive to create partnerships that benefit both parties, and we have built relationships with several of our vendors to include more than just buying parts,” says COO Aaron Glaser.

“Partners like 3M have provided Glaser’s with more than just materials. Our shop uses 3M exclusively for abrasives and adhesives because of the education and reporting that they offer.”

Numerous in-house training classes have been conducted by 3M to bolster the skills of the body and paint personnel, and paint vendor Gipe Automotive – a family owned business based in Owensville, Ky. dating back to 1931 – facilitates a monthly 3M-produced Performance Analysis Tool prepared for all three of the Glaser (rhymes with plaster) locations.

“This tool gives us great detail of our materials usage, something that we had a hard time accurately tracking before partnering with 3M,” according to Aaron. “It is great to have a vendor report to us exactly what our materials profitability is and what categories we need to work on.”

An extensive quarterly Performance Analysis Tool review offers additional insights. “The quarterly review goes into detail of every grit of sandpaper and every tube of adhesive; we have worked together to develop a materials budget for every 3M part number that we have,” he says.

The report shows actual usage versus usage budgeted figures “so we can easily track waste and see where the training opportunities are with our staff. Detail of that level would take us a tremendous amount of time to do internally, but to have a vendor partner step in and track it for us has been tremendous for our business,” says Aaron. “Not only are we seeing an 18 percent increase in materials profitability, but the training has also increased our body-labor efficiency.”

Zero body shop experience

Training is an elemental Glaser attribute. “Our people are our greatest asset and our biggest competitive advantage. Our No. 1 focus is our people. We hire off of attitude and heart instead of technical experience. We have hired many people who have zero body shop experience and trained them from the ground-up because we believe they are good people who have ambition and heart,” Aaron reports.

“The managers of two of our locations had never stepped foot in a body shop six years ago. Both these people were hired based off their attitude and character. Of these two shops, there are nine administrative staff in the shops and only two of them had body shop experience prior to working for Glaser’s. Almost the entire administrative staff were hired and trained by us so that we can teach them the top-notch customer service that we expect.

“Many of the people in our shops were people that we hired with little or no experience and trained them. This process takes us a lot longer to on-board them and get new hires up to speed, but they do not come to us with bad habits. We can train and coach them to be top-notch players to deliver the high level of service and quality that our customers deserve.”

Aaron goes on to point out that “we have some of the best-trained, well-educated technicians in town.” The shops are I-CAR Gold Class, and all of the painters are PPG certified in waterborne basecoat.

“We focus on staying on top of the latest OEM technology. We were the first in Louisville to purchase the asTech2 scan tool to perform OEM completion scans on repaired vehicles. We are active in the CIC Insurer/Shop Relations Committee, and as far as dealing with advanced materials, our body departments are trained in aluminum repairs – including the new F-150 – and our Shepherdsville shop has a composite department that specializes in carbon fiber repairs.”

Having earned a Better Business Bureau A+ rating, the shop has obtained a host of automaker repair certifications to further ensure stellar customer satisfaction.

Established 30 years ago, the operation is owned by Aaron’s parents, Gene and Susan Glaser.

“Gene Glaser has always been a gearhead,” Aaron recounts. “He was a construction worker by trade but spent all his time and money tinkering with cars. When he was starting his family he worked construction to pay his bills, but worked nights in the garage working on cars to make extra money for his drag racing habit.”

It was a construction-trade layoff in 1986 that finally put Gene on the path toward founding his own auto repair business.

“After a short job search came up dry, he decided to start Glaser’s Automotive. He rented a 900-square-foot building and started fixing cars. When the business was started, it was an all-encompassing automotive shop. Gene did anything from mechanical work to body work,” says Aaron. “Susan was not one to sit and watch. She took classes at the local community college on upholstery. She went and bought an industrial sewing machine, and she did automotive interiors at the shop while also running the office and accounting at the shop.”

Expansion came quickly as Craig Davis became the first employee that the couple brought onboard during the first year in business, and he has since moved up to manage the Jeffersontown location. “Craig’s years of hard work and dedication have been integral to the success of the company,” according to Aaron.

Two years later, the company was again in expansion mode, culminating in construction of the 7,000-square-foot Jeffersontown shop. Four years hence, “business was doing great,” and a 10,000-square-foot addition was added to the building.

Another opportunity arose in 1998. “A competitor shop was going out of business, so Team Glaser’s decided it was time to expand. After some cleaning and light renovations to the building, Glaser’s Collision Center of Audubon Park was born,” says Aaron.

“Our second location actually came about because of how we treated a parts delivery driver. A parts delivery driver was actually a landlord for a building that was being used as a body shop. That shop ran into trouble with the IRS and was shut down,” he says. “The delivery driver came to Gene and told him that he actually owned the building and respected Glaser’s for the way that we treated him every time that he came to bring us parts, so he asked if we would like to take over the rent and run a shop out of there. This invitation is what sparked the second location for Glaser’s,” Aaron explains.

“Although not an overnight success, this shop eventually became a great location. The business steadily grew and we built a great team at this location.” In 2008 a new structure was constructed at the site. “The new building gave us the opportunity to upgrade equipment and give the location a face lift.”

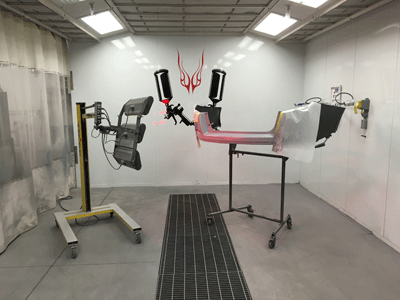

A new paint booth and prep decks from Global were installed along with air conditioning throughout the entire facility. In addition, two Car-O-Liner frame racks with full measuring equipment, Pro-Spot aluminum dent repair equipment, a silicone bronze smart welder and a Car-o-Liner resistance spot welder were also added.

In 2009, it was time to add a third shop. Citing the facility’s “humble beginnings,” Aaron describes his entry into the industry at age six: “Being a start-up business, my parents worked around the clock to make sure their business was a success, so naturally I was there by default. Like most, I started out sweeping floors and washing cars. The paint shop always intrigued me. As a kid, I started taking bicycles and painting them. I had a little side business taking old bikes and painting them and reselling them for a profit. My uncle owned an antique shop. Once he saw what I was doing, he would go buy old antique Schwinn bicycles and have me restore them. I would paint and re-chrome them and he would sell them in his antique store.

“As I got older,” Aaron continues, “the bicycles were traded for race cars. Growing up in a drag racing family, I started painting my own junior dragsters at age 14. It didn’t take long for my friends and competitors to start having me paint their cars. Over the next 10 years we grew a custom painting business and had a reasonable amount of success, painting some high-end custom jobs and winning numerous car shows.

“Once I was in my mid 20s it was time to decide whether to pursue my custom business or work full-time for the family business. Dad was at the point that if he did not have a predecessor, he was going to start working on his exit plan,” Aaron reports.

“I enjoyed the freedom of the custom painting, but my heart was always at the body shop,” he says. “I grew up watching my parents put their heart and soul into building a great business, and I had always wanted to carry that forward. So I decided to shut down the custom business and go back to my roots in the body shop.

Aaron’s custom enterprise was thus converted into a third body shop in 2009.

“When we opened it as a collision center, I was the sole employee. I wrote the estimate and sold the job, then went in the back and did the repair, painted it and delivered it back to the customer,” he recalls. “It didn’t take long to outgrow that and start hiring people. The first person that we hired to help in the office was Nathan Ashbaugh. He was a bright-eyed young kid who knew nothing of body repairs, but had an outstanding positive attitude. After years of coaching and training, Nate is now the store manager and is doing a phenomenal job of running that location. I have handed daily operations off to Nate so that I can split my time between the two shops.”

Improvements wherever necessary

The business thrives by stressing “communication, communication, communication,” says Aaron, especially when dealing with insurers. “Our relationships with insurance providers are just like any other relationship – they live or die on communication. If we understand what is important to them, we can work to provide them the results that they are looking for. We like to meet quarterly with our DRP (direct repair program) partners to discuss our performance and what we can do to improve,” he notes.

“We strive to keep the communication open, especially at a local level, so that if either of us has an issue we can discuss it and work it out before it becomes a problem.”

The company also “takes our scorecards very seriously. Any scorecard information shared from our insurance partners is reviewed with the shop as a team and discussed so that we can make improvements wherever necessary.”